How is Smart Manufacturing Transforming Aluminum Extrusion Processes?

Smart manufacturing is changing the aluminum extrusion industry. This approach uses advanced technologies to improve efficiency, quality, and sustainability. As manufacturers adopt smart solutions, they enhance their processes and meet market demands. This article explores how smart manufacturing is transforming aluminum extrusion.

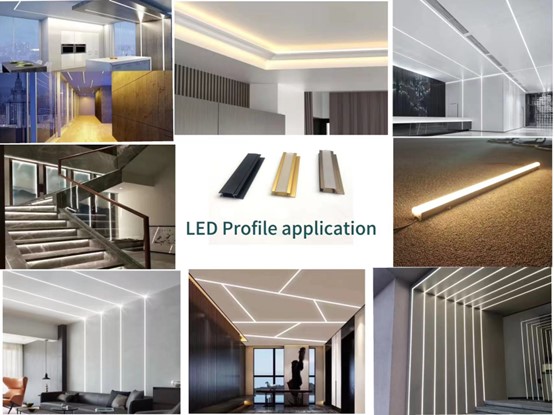

Image Source: hugh-aluminum.com

Understanding Aluminum Extrusion

What is Aluminum Extrusion?

Aluminum extrusion shapes aluminum alloy by forcing it through a die. This process creates specific profiles that are lightweight and strong. Industries use these profiles in construction, automotive, and aerospace applications.

Key Benefits of Aluminum Extrusion

- Custom Shapes: Manufacturers can create complex designs.

- Strength-to-Weight Ratio: Aluminum extrusions provide high strength while remaining lightweight.

- Corrosion Resistance: Aluminum resists corrosion, increasing durability.

- Energy Efficiency: The extrusion process uses less energy than other methods.

The Role of Smart Manufacturing

What is Smart Manufacturing?

Smart manufacturing uses technologies like the Internet of Things (IoT), artificial intelligence (AI), and automation to optimize production. It enables real-time data collection and analysis, leading to better efficiency and reduced waste.

Key Technologies in Smart Manufacturing

- IoT Sensors: These devices collect data from machines, providing insights into performance.

- AI and Machine Learning: These technologies analyze data to predict maintenance needs and optimize production schedules.

- Automation: Automated systems streamline tasks, reducing errors and increasing productivity.

Benefits of Smart Manufacturing in Aluminum Extrusion

Improved Efficiency

Smart manufacturing enhances efficiency by automating repetitive tasks and optimizing workflows. IoT sensors monitor machine performance in real time, allowing operators to identify issues early. This approach minimizes downtime and maximizes productivity.

Enhanced Quality Control

Smart technology improves quality control measures. AI algorithms analyze production data to detect problems and ensure products meet specifications. This reduces defects and enhances overall product quality.

Cost Reduction

By optimizing processes and minimizing waste, smart manufacturing lowers production costs. Real-time monitoring of energy use helps identify inefficiencies, allowing manufacturers to adjust operations for savings.

Sustainability Improvements

Smart manufacturing promotes sustainability by reducing waste and energy consumption. IoT devices track material usage and highlight areas for improvement. Manufacturers can also use recycled aluminum more effectively, supporting a circular economy.

Real-world Applications of Smart Manufacturing in Aluminum Extrusion

Predictive Maintenance

Predictive maintenance uses data analytics to forecast equipment failures before they happen. By analyzing machine performance patterns, manufacturers can schedule maintenance proactively. This approach reduces unexpected downtime and extends equipment lifespan.

Supply Chain Optimization

Smart manufacturing enhances supply chain management by providing real-time visibility into inventory levels and production schedules. Manufacturers can track raw materials from suppliers to finished products, improving transparency and efficiency.

Enhanced Customization

Smart technology allows manufacturers to respond quickly to customer demands for customized products. Advanced software enables rapid design changes and efficient production adjustments, meeting specific client needs without delays.

Challenges in Implementing Smart Manufacturing

While the benefits of smart manufacturing are significant, challenges exist. High initial costs for technology implementation can deter some companies. Integrating new systems with existing infrastructure may require adjustments.

Training employees to use new technologies is essential for successful implementation. Companies must invest in workforce development to ensure staff can operate smart manufacturing systems effectively.

Conclusion

Smart manufacturing is transforming aluminum extrusion processes by improving efficiency, quality control, cost-effectiveness, and sustainability. As the industry adopts these advanced technologies, manufacturers will better meet evolving market demands.

Embracing smart solutions will help companies enhance operations while contributing to a sustainable future in aluminum extrusion. Adapting to these changes will be crucial for staying competitive in a digital landscape.